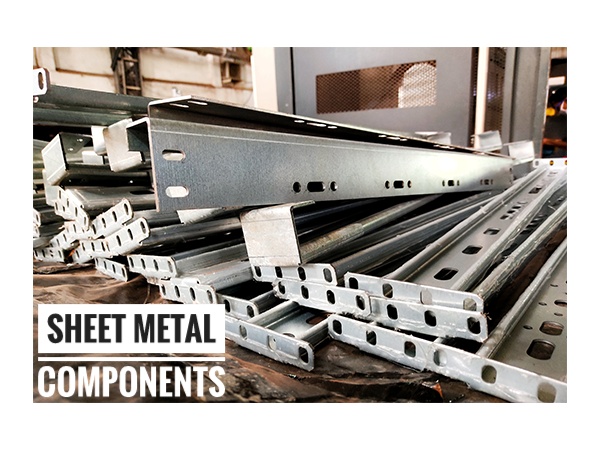

Sheet Metal Components

- Specialisation: We produce sheet metal components to specifications that go into a variety of products like generators, pumps, panels, compact sub-stations, UPS, etc.

- Design: We have strong designing capabilities to meet varied customer demands, with a knowledgeable, skilled & experienced team.

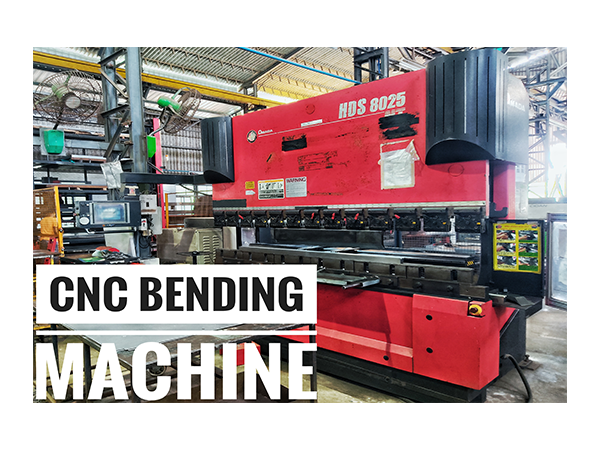

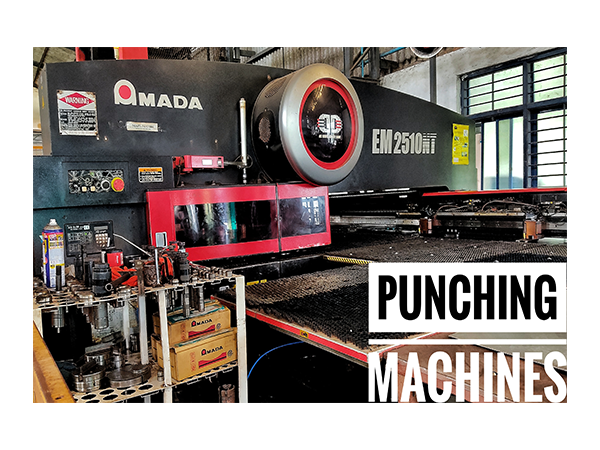

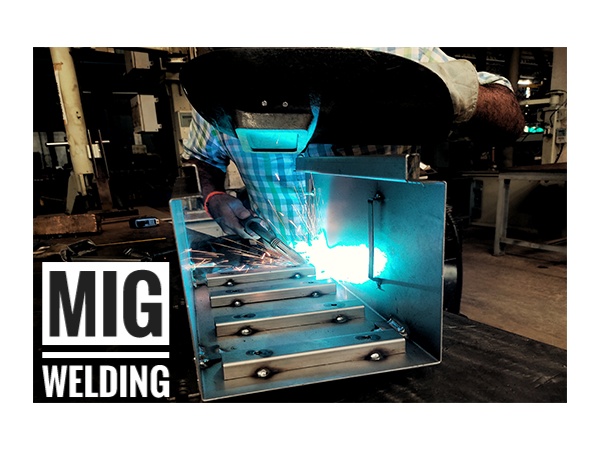

- Facilities: A fully integrated sheet metal manufacturing facility with punching, shearing & bending operations, fabrication, pre-treatment and powder coating processes.

- Equipment: The machine shop includes an Amada laser cutting machine, Amada turret punch presses, Amada press brakes, a Safan press brake and a shearing machine. The fabrication shop comprises of MIG welding machines. We also have an automated zinc phosphate pre-treatment plant through which all parts are sent after fabrication. A state-of-the-art automatic powder coating plant is used for powder coating the components to give them the desired quality finish.

Latching & Engineering Products

- Commitment: Committed to supply as per customer specifications, with on-time deliveries and at competitive rates.

- Customers: Engaged in supplying latching and engineering products to a variety of industries, including generator manufacturers, sheet metal fabricators, and heavy equipment manufacturers.

- Approach: Process-based and innovative approach to manufacturing

- New Product Development: Provide new product development at an accelerated pace to meet customer requirements.

- Capabilities: Include metal casting, sheet metal, plastic moulded, and special assemblies.

- Infrastructure: Power presses ranging from 30 tons to 500 tons capacity, pressure die casting machine, stud welding machine and abrasive belt grinder.